Learn how our manufacturing processes allow us to deliver various products for our customers.

Learn how our manufacturing processes allow us to deliver various products for our customers.

Learn how our manufacturing processes allow us to deliver various products for our customers.

We work with world-class brands in a variety of industries to bring their visions to life through style, performance and protection.

COMPANY

2021-11-09

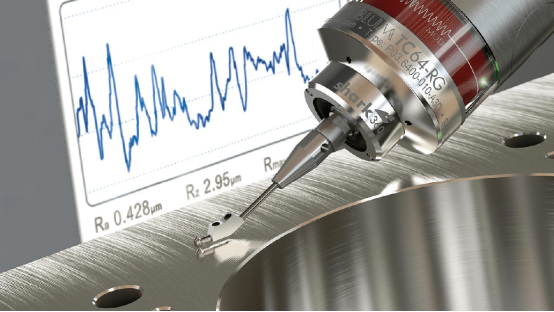

Surface roughness is the measure of the finely spaced micro-irregularities on the surface texture which is composed of three components, namely roughness, waviness and form.

Surface roughness is generally formed by the machining method and other factors, such as the friction between the tool and the surface of the parts during the machining, the plastic deformation of the metal surface during chip separation, and the high frequency vibration in the machining process. Due to the different processing methods and the materials of the workpieces, the depth, density, shape and texture of the traces left on the processed surface are different.

The surface roughness has great effects on the parts in the following aspects:

1. Effect on the wear resistance of the parts: The rougher the surface and the smaller the effective contact area between the mating surface, the greater the pressure and the friction. Then the wear of the parts is faster.

2. Effect on the stability of the Fit. For clearance fit: the rougher the surface is, the easier it is to wear, so that the gap increases gradually in the process of the work; but for interference fit: because the microscopic convex peak is squeezed flat during assembly, the actual effective interference is reduced and the connection strength is reduced.

3. Effect on the fatigue strength. There are large troughs on the rough surface of the parts, which are very sensitive to stress concentration, like sharp corners and cracks, and thus affect the fatigue strength of parts.

4. Effect on corrosion resistance. The corrosive gas or liquid can easy go through the microscopic concave valley of the rough surface into the inner layer of the metal and resulting in surface corrosion.

5. Effect on sealing performance. Rough surfaces do not fit tightly together, so gas or liquid leaks through gaps between contact surfaces.

Besides, the surface roughness has also effects on the coating, thermal conductivity and contact resistance, reflective ability and radiation performance, liquid and gas flow resistance.

Generally speaking, the small surface roughness value will improve the fit quality, reduce wear and prolong the service life of the parts, but processing cost of the parts will be increased. Therefore, the surface roughness value should be selected correctly and reasonably. Customers can also consult us and we will help the customer to fix the right surface roughness value according to their requirement.