Learn how our manufacturing processes allow us to deliver various products for our customers.

Learn how our manufacturing processes allow us to deliver various products for our customers.

Learn how our manufacturing processes allow us to deliver various products for our customers.

We work with world-class brands in a variety of industries to bring their visions to life through style, performance and protection.

COMPANY

2022-07-20

Generally speaking, special casting is a casting method that makes the casting thinner, stronger and more precise. Special casting refers to various casting methods other than sand casting. Commonly used special casting method includes investment casting, plaster precision casting, ceramics precision casting, lost foam casting, permanent mold casting, pressure casting, low pressure casting, counter-pressure casting,suction casting, squeeze casting, centrifugal casting, continuous casting, the semi-continuous casting, shell mold casting, graphite mold casting, electroslag smelting castin, etc. Today, we will mainly introduce one of the methods: investment precision casting.

First. the Concept of Investment Precision Casting

Investment casting is an advanced near-net forming process. It is a casting method in which a fusible primary model and a core are used to form a casting. Investment casting can produce precision and complex castings of various alloys, which are close to the final shape and size of the parts, and it can be used directly without machining or with little machining. It is usually suitable for the production of small and medium precision complex castings, with various production batches.

Second. Process of Investment Casting

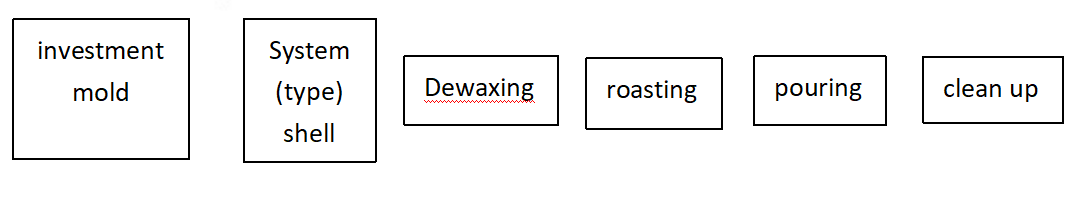

Make investment mould-make mold shell- dewaxing- baking-pouring-cleaning

Third. the Advantages of Investment Casting

1.Advantages: (1)The dimensional accuracy of investment castings is relatively high, which is generally up to CT4-6 (For sand casting, it is CT10~13, for pressure casting, it is CT5~7).(2)The surface finish of investment mold is high. When pressing the investment mold, the pressure mold with high surface finish of the cavity is used. In addition, the shell is made of special refractory materials and coatings on the investment mold, so the finish is generally up to Ra.1.6~3.2μm.(3)nvestment casting can save machinery work, it can cast various alloy castings while saving cost.