Learn how our manufacturing processes allow us to deliver various products for our customers.

Learn how our manufacturing processes allow us to deliver various products for our customers.

Learn how our manufacturing processes allow us to deliver various products for our customers.

We work with world-class brands in a variety of industries to bring their visions to life through style, performance and protection.

COMPANY

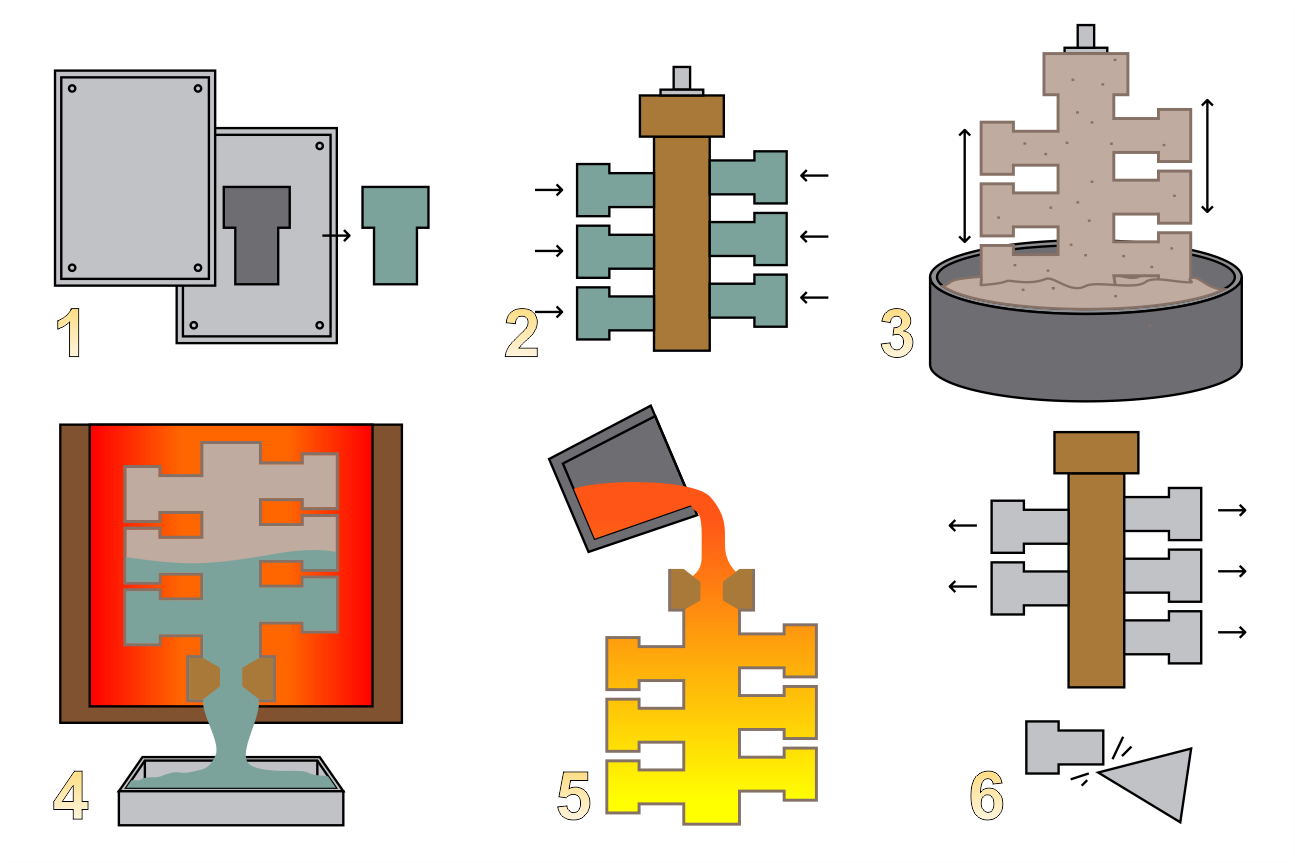

Investment Casting, also known as Lost Wax Casting, is a precision casting process that provides design flexibility and significant cost advantages.

The Investment Casting process involves pouring molten metal into a mold that has been created using a wax model. Once the mold is made, the wax model is melted and drained away.

One such advantage is the ability to make more intricate forms—even forms with undercuts. Also, the investment casting process leaves a very smooth surface, which is created without a parting line—something that would be unavoidable in other processes.

With new alloys developed that allow for more complex parts to be cast, the process of combining several parts together to get the intricate shape can be eliminated. This not only saves time and money, but it also diminishes the chances that an error could occur while combining the parts by welding or assembling.

Investment casting is very ideal to produce a wide range of products across different industries, various kinds of Steels and Alloys for your option, diminishing the need for designers to worry about the production of the casting they have visualized.

Fittings

Valve housings

Instrument housings

Pump housings

Impellers

Automotive parts

Railway parts

Floor drains

Lock parts

Construction parts

Parts for food & beverage

Stainless steel Casting

Steel Casting

Stainless steel Fitting

Stainless steel Press fitting

Steel Press fitting

Wax Injection – Wax Piece Tree Assembly – Shell Moulding – Wax Remove – Melting and Pouring – CNC Machining

CONTACT US

CONTACT US

Tel: +86 28 8666 2540

Fax: +86 28 8666 2034

Tel: 469.450.1671

Tel: +49 2406 6676 275